- Company

- About ElectronAix

- News

- Jobs

- Product

- Purchasing

- Technology

- Contact

- The Way to us

Do you prefer individual solutions and individual support? Welcome to ElectronAix!

Your contact for crimped connections is

Peter Stremmer

+49-241-18906-91

Contact us!

Your contact for crimped connections is

Peter Stremmer

+49-241-18906-91

Contact us!

Customised cable assemblies with crimp style connectors made by ElectronAix

Crimping is an established and reliable technology for cable assemblies ▼

When crimping wires, a mechanical connection between the terminal and the wire is made. To produce such assemblies, wires and crimp terminals are fed into an automatic crimping machine or semi-automatic crimping machine. For small batch sizes or exotic crimp contacts, hand crimp tools – crimping pliers - can be used.

The machine process strips the wires with the correct length and feeds the wires and the crimp terminals to the crimping tool. The crimping tool forms the wire- and the isolator crimp. A good crimp connection is gas-tight around the conductor crimp. This is an essential quality criterion. Only gas-tight connections are stable in the long run, as the copper in the contact area cannot oxidize.

This technique creates a crimp connection between the wire and the contact. This crimped connection is homogeneous and non-detachable. When crimping, it is important that the contact, the wire and the crimping tool fit together exactly. ElectronAix is an expert for the automated production of crimp style cable assemblies. Our team supports you with the selection of the right material and the design of your assembly.

After crimping, the crimped wires need to be assembled or "plugged" into the housing of a connector according to the connection plan. Cable assemblies with crimped terminals are thus a very good alternative to soldered connections.

Crimp technology is very reliable connection for cable assembly and combines the advantages of the automated process with the flexibility of manual assembly.

The machine process strips the wires with the correct length and feeds the wires and the crimp terminals to the crimping tool. The crimping tool forms the wire- and the isolator crimp. A good crimp connection is gas-tight around the conductor crimp. This is an essential quality criterion. Only gas-tight connections are stable in the long run, as the copper in the contact area cannot oxidize.

This technique creates a crimp connection between the wire and the contact. This crimped connection is homogeneous and non-detachable. When crimping, it is important that the contact, the wire and the crimping tool fit together exactly. ElectronAix is an expert for the automated production of crimp style cable assemblies. Our team supports you with the selection of the right material and the design of your assembly.

After crimping, the crimped wires need to be assembled or "plugged" into the housing of a connector according to the connection plan. Cable assemblies with crimped terminals are thus a very good alternative to soldered connections.

Crimp technology is very reliable connection for cable assembly and combines the advantages of the automated process with the flexibility of manual assembly.

Crimped connections are ideal for internal and external wiring starting with AWG32 ▼

In most cases, cable assemblies with crimped terminals are used for internal wiring. They serve as LVDS cables with small cross-sections and twisted pairs for data transmission. This cable assembly is suitable for connecting displays or for bus wiring of USB2.0 or CAN bus signals.

With large cross-sections, crimp connections are used for power transmission.

The connector housings have an open design. This is the reason, why overmoulding or IP protection costs great effort. Accordingly, cable assemblies with crimp contacts are mostly used for internal wiring. For external wiring, there are special crimp connectors with additional seals that enable use even under harsh conditions.

With large cross-sections, crimp connections are used for power transmission.

The connector housings have an open design. This is the reason, why overmoulding or IP protection costs great effort. Accordingly, cable assemblies with crimp contacts are mostly used for internal wiring. For external wiring, there are special crimp connectors with additional seals that enable use even under harsh conditions.

Crimped connections: Details and a good process control matter ▼

Making a good crimp connection is simple: The size and shape of the crimping tool must match the respective terminal and the outer diameter and copper cross-section of the wire. Experience has shown that it is precisely these factors that are decisive for a high reliable connection

ElectronAix always checks whether these quality-critical fundamentals are fulfilled.

The crimping tools wear out during crimping. Defined quality standards such as IPC-620 and effective In-Process Control (IPC) ensure stable production. All our partners regularly monitor the crimp dimensions and manufacture according to IPC 620.

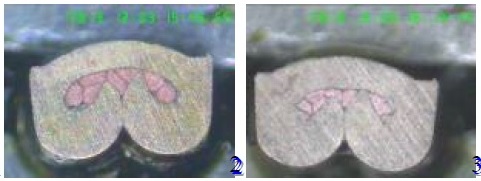

For the First Article Inspection, we make a cross section report to check whether the correct crimping tool has been selected and whether the crimp is gas tight. This is the only way to ensure a permanently good connection.

Appropriate measures in production ensure, that that the crimping is correct. A 100 percent electrical test proof, that the crimping the connectors is as requested.

ElectronAix always checks whether these quality-critical fundamentals are fulfilled.

The crimping tools wear out during crimping. Defined quality standards such as IPC-620 and effective In-Process Control (IPC) ensure stable production. All our partners regularly monitor the crimp dimensions and manufacture according to IPC 620.

For the First Article Inspection, we make a cross section report to check whether the correct crimping tool has been selected and whether the crimp is gas tight. This is the only way to ensure a permanently good connection.

Appropriate measures in production ensure, that that the crimping is correct. A 100 percent electrical test proof, that the crimping the connectors is as requested.

Figure: cross section analysis of a crimped terminal

You will find all types of cable assemblies with crimp style connectors at ElectronAix ▼

Our main types are:

- cable assemblies from UL-certified production with UL material.

- cable assemblies with original connectors of the manufacturers JAE, Hirose, Molex, Tyco, JST, etc./span>

- cable assemblies with low-cost connector equivalents

- cable assemblies with customer-specific shield connection

- cable assemblies with twisted pairs

- cable assemblies with moulded sleeves or connectors up to IP69K

Supply chain solutions for cable assemblies by ElectronAix ▼

SAP is our most important tool

We work with an ERP-system from SAP and map all flows of goods there, from the procurement of raw materials to the storage of raw materials, the inventories in our buffer warehouse in Aachen and all the way to the deliveries of your orders.

Our ERP-system thus combines all the functions we need for our business operations, ensuring maximum transparency, and data integrity.

Our ERP-system thus combines all the functions we need for our business operations, ensuring maximum transparency, and data integrity.

Documentation and data security

The most important information about the article life cycle is integrated into our ERP-system: Clarifications and technical changes are thus accessible and available at any time if required, for example during order entry.

To ensure the highest level of data security, our server is mirrored, and both servers are also housed in different fire protection areas. In addition, all data is backed up daily to a German cloud. An external partner keeps our firewall and virus scanner permanently up to date.

To ensure the highest level of data security, our server is mirrored, and both servers are also housed in different fire protection areas. In addition, all data is backed up daily to a German cloud. An external partner keeps our firewall and virus scanner permanently up to date.

Project planning and buffer storage

We purchase critical components from Aachen This gives us 100% control of material management and - flow. During the ramp up we can agree with you on buying critical parts from the BOM-List in advance. This supports a smooth project ramp up and maximum supply security for your benefit. It gives you more time to finalize the design of your assembly. During the lifecycle we can keep a buffer stock of the critical components. This shortens lead times gives you flexibility. In case of minimum order quantities e.g. for raw cable, we can arrange to keep the surplus in our factory for future orders.

Origin of supply

We mainly work with companies that are based in Taiwan. There, we focus on a small number of experts. Most of them have production lines in China (Mainland). In recent years we have expanded our portfolio and can also offer you solutions for cable assemblies from Korea, Malaysia, Taiwan, Thailand and Vietnam.

20 years of experience, short time to market, high quality, testing ▼

Short time to market

Many years of experience, attention to detail and passion for our products will quickly help you to find the cable assembly with crimp style connector that is precisely tailored to your needs.

We aim to quickly provide you with helpful information, the right drawing and appropriate samples. This reduces your time to market. Our buffer stock of connectors and contact systems help you to find a solution quickly and to achieve short delivery times.

We aim to quickly provide you with helpful information, the right drawing and appropriate samples. This reduces your time to market. Our buffer stock of connectors and contact systems help you to find a solution quickly and to achieve short delivery times.

High Quality

ISO9001, ISO13485 and IATF16949 certified production lines are indicators of the high quality standard of our products and ensure your safety and satisfaction.

All products come from a largely automated process with automatic soldering and crimping and 100 percent electrical testing. Our distribution and logistics processes are certified according to ISO9001 and audited according to VDA.

All products come from a largely automated process with automatic soldering and crimping and 100 percent electrical testing. Our distribution and logistics processes are certified according to ISO9001 and audited according to VDA.

Tests

You require specific tests, such as bending cycles, lengths or test reports? If so, ElectronAix is the perfect partner for you. We will coordinate all details with you individually.

"Our strength are series starting at 1000 pieces. We will provide to you a drawing for approval, samples for approval and a one-time preproduction run. The serial products always comply with the samples – they always come from the same production and are always made of the same material. Feel free to contact us."

Your personal contact for crimped cable assemblies

Mr. Peter Stremmer

+49-241-18906-91

+49-241-18906-91

peter.stremmer@electronaix.com

peter.stremmer@electronaix.com

.png) Contact form

Contact form

Mr. Peter Stremmer

peter.stremmer@electronaix.com

peter.stremmer@electronaix.com