- Company

- About ElectronAix

- News

- Jobs

- Product

- Purchasing

- Technology

- Contact

- The Way to us

Cable assemblies with molded connectors by ElectronAix for custom cable assemblies

Cable assemblies with overmoulded connectors: cost advantages due to simple processing ▼

For cable assemblies with moulded connectors , the connector housing is fitted using a plastic injection moulding. Several process steps are necessary for this:

First, wires and contacts are connected to each other. For the most part, this is done in a soldering process. This is followed by fixing with a hotmelt adhesive or internal overmoulding. The last step is an outer overmoulding with a PVC or PUR material. Alternatively, overmoulding using a low-pressure injection mold is also possible.

In exceptional cases, we assemble connector housings. With this method, the connector housing consists of several components: the contact carrier, the housing hoods as well as seals and strain reliefs. These components are assembled like a kit after the electrical connection has been made. The process is labour intensive.

However, a simple and fast overmoulding process means considerable cost advantages compared to the complex assembly – overmoulded connectors are significantly cheaper due to the easy manufacturing process.

First, wires and contacts are connected to each other. For the most part, this is done in a soldering process. This is followed by fixing with a hotmelt adhesive or internal overmoulding. The last step is an outer overmoulding with a PVC or PUR material. Alternatively, overmoulding using a low-pressure injection mold is also possible.

In exceptional cases, we assemble connector housings. With this method, the connector housing consists of several components: the contact carrier, the housing hoods as well as seals and strain reliefs. These components are assembled like a kit after the electrical connection has been made. The process is labour intensive.

However, a simple and fast overmoulding process means considerable cost advantages compared to the complex assembly – overmoulded connectors are significantly cheaper due to the easy manufacturing process.

IP classification for waterproof cable assemblies ▼

Depending on the overmoulding, it is possible to achieve IP classes of up to 69K. These assemblies are also suitable for use in harsh environments.

Waterproof cable assemblies that feature overmoulded connectors are therefore a safe and reliable solution for outdoor use.

Waterproof cable assemblies that feature overmoulded connectors are therefore a safe and reliable solution for outdoor use.

Overmoulded connectors cable assemblies for many applications ▼

Due to the overmoulding of the connector, these cable assemblies are mainly used outside of devices. The combination of a flexible manufacturing process and high safety due to the IP classification allows moulded connectors for numerous applications.

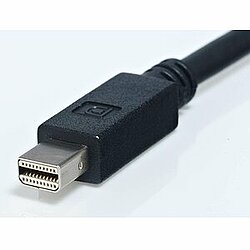

Typical examples are cable assemblies with D-SUB, USB, Type-C, HDMI, DVI, Displayport, waterproof round connectors M5/M8/M12, network cables, power cords and many more.

The injection moulds can also be modified with a small buget. This means that individual moulds for customer-specific applications are easy possible. ElectronAix offers moulded connectors with magnetic connection as well as individual solutions for customised USB cables (USB 2.0 cables, USB 3.0 cables, USB-A plug type-C connectors and much more).

An alternative to an overmoulded plug connectors is a grommet that is moulded to a jacket cable. There are different reasons for choosing this version: A grommet safes space, it can reduce costs, when the cable is firmly connected to the application. Individual sleeves and strain reliefs can be realised with little effort.

Another application for plastic overmoulding are distributors, from simple Y-distributors with three cable outlets to multiple distributors. Inside the distributor there is always wiring (either on a printed circuit board or freely wired). The distribution point is then overmoulded to save as much space as possible.

Typical examples are cable assemblies with D-SUB, USB, Type-C, HDMI, DVI, Displayport, waterproof round connectors M5/M8/M12, network cables, power cords and many more.

The injection moulds can also be modified with a small buget. This means that individual moulds for customer-specific applications are easy possible. ElectronAix offers moulded connectors with magnetic connection as well as individual solutions for customised USB cables (USB 2.0 cables, USB 3.0 cables, USB-A plug type-C connectors and much more).

An alternative to an overmoulded plug connectors is a grommet that is moulded to a jacket cable. There are different reasons for choosing this version: A grommet safes space, it can reduce costs, when the cable is firmly connected to the application. Individual sleeves and strain reliefs can be realised with little effort.

Another application for plastic overmoulding are distributors, from simple Y-distributors with three cable outlets to multiple distributors. Inside the distributor there is always wiring (either on a printed circuit board or freely wired). The distribution point is then overmoulded to save as much space as possible.

Cable assemblies with overmoulded connectors by ElectronAix – individual solutions with high reliability ▼

Automatic soldering

The most critical process step for the quality of cable assemblies with overmoulded connectors is the connection between the wire and the connector. This is usually realised with a soldering. Overmoulded connectors and cable assemblies from ElectronAix are automatically soldered whenever possible. As a result, you get overmoulded connectors manufactured in a stable process with a high-quality and durable electrical connection.

Small tolerances of dimensions for IP-rated applications

Tight tolerances are often required for sleeves and strain reliefs for IP-rated applications. Thanks to modern injection moulding processes and our many years of experience in this field, we can also realise small tolerances for your applications.

Customised modifications and raw cables

For cable assemblies with moulded connectors, there is often a request for a customer-specific raw cable. We can produce all kind of raw cables with special color, LSZH, hybrid cables for power and data etc. A customised raw cable is always subject to a minimum order quantity -MOQ- of 1000m, but usually 3000m.

The raw cable MOQ can be assembled for several production lots. In our processes and ERP-system, we automatically map such cases with a purchase commitment. It is very transparent at any time which remaining quantity is still available. Furthermore, the injection mould must be adapted to the outer diameter of the cable. At ElectronAix we manage both for you. We manage the minimum order quantities with you via purchase commitments. The adaptation of moulds is a standard process for us when it comes to customer-specific solutions.

We supply customised solutions for:

The most critical process step for the quality of cable assemblies with overmoulded connectors is the connection between the wire and the connector. This is usually realised with a soldering. Overmoulded connectors and cable assemblies from ElectronAix are automatically soldered whenever possible. As a result, you get overmoulded connectors manufactured in a stable process with a high-quality and durable electrical connection.

Small tolerances of dimensions for IP-rated applications

Tight tolerances are often required for sleeves and strain reliefs for IP-rated applications. Thanks to modern injection moulding processes and our many years of experience in this field, we can also realise small tolerances for your applications.

Customised modifications and raw cables

For cable assemblies with moulded connectors, there is often a request for a customer-specific raw cable. We can produce all kind of raw cables with special color, LSZH, hybrid cables for power and data etc. A customised raw cable is always subject to a minimum order quantity -MOQ- of 1000m, but usually 3000m.

The raw cable MOQ can be assembled for several production lots. In our processes and ERP-system, we automatically map such cases with a purchase commitment. It is very transparent at any time which remaining quantity is still available. Furthermore, the injection mould must be adapted to the outer diameter of the cable. At ElectronAix we manage both for you. We manage the minimum order quantities with you via purchase commitments. The adaptation of moulds is a standard process for us when it comes to customer-specific solutions.

We supply customised solutions for:

- cable assemblies with moulded connectors, grommets and Y-distributors

- cable assemblies with customised jacket cables

- cable assemblies with customised sleeves

- cable assemblies with customised connectors

- cable assemblies with customised cable outlets

- cable assemblies with magnetic connectors

- customised packaging

- customer-specific labels

- jacket cables with particularly small outer diameter

- drag chain capable jacket cables

- hybrid solutions e. g. USB + ethernet + power in one jacket

- jacket cables with PVC or PUR jacket

- jacket cables with steel reinforcement

- with UL material and/or from UL-certified production site

- with certificate or tests e. g. UL, USB, HDMI etc.

Supply chain solutions for cable assemblies by ElectronAix ▼

SAP is our most important tool

We work with an ERP-system from SAP and map all flows of goods there, from the procurement of raw materials to the storage of raw materials, the inventories in our buffer warehouse in Aachen and all the way to the deliveries of your orders.

Our ERP-system thus combines all the functions we need for our business operations, ensuring maximum transparency, and data integrity.

Our ERP-system thus combines all the functions we need for our business operations, ensuring maximum transparency, and data integrity.

Documentation and data security

The most important information about the article life cycle is integrated into our ERP-system: Clarifications and technical changes are thus accessible and available at any time if required, for example during order entry.

To ensure the highest level of data security, our server is mirrored, and both servers are also housed in different fire protection areas. In addition, all data is backed up daily to a German cloud. An external partner keeps our firewall and virus scanner permanently up to date.

To ensure the highest level of data security, our server is mirrored, and both servers are also housed in different fire protection areas. In addition, all data is backed up daily to a German cloud. An external partner keeps our firewall and virus scanner permanently up to date.

Project planning and buffer storage

We have critical components in stock on site in Aachen. This gives us 100% control of material management and - flow. During the ramp up we can agree with you on buying critical parts from the BOM-List in advance. This supports a smooth project ramp up and maximum supply security for your benefit. It gives you more time to finalize the design of your assembly.

During the lifecycle we can keep a buffer stock of the critical components. This shortens lead times gives you flexibility.

In case of minimum order quantities e.g. for raw cable, we can arrange to keep the surplus in our factory for future orders.

During the lifecycle we can keep a buffer stock of the critical components. This shortens lead times gives you flexibility.

In case of minimum order quantities e.g. for raw cable, we can arrange to keep the surplus in our factory for future orders.

Origin of supply

We mainly work with companies that are based in Taiwan. There, we focus on a small number of experts. Most of them have production lines in China (Mainland). In recent years we have expanded our portfolio and can also offer you solutions for cable assemblies from Korea, Malaysia, Taiwan, Thailand and Vietnam.

20 years of experience, short time to market, high quality, testing and cleanliness ▼

Short time to market

Many years of experience, attention to detail and passion for our products will quickly help you to find the cable assembly with moulded connectors that is precisely tailored to your needs.

We aim to quickly provide you with helpful information, the right drawing and appropriate samples. This reduces your time to market. Our buffer stock of connectors, contact systems and cable assemblies help you to find a solution quickly and to achieve short delivery times.

We aim to quickly provide you with helpful information, the right drawing and appropriate samples. This reduces your time to market. Our buffer stock of connectors, contact systems and cable assemblies help you to find a solution quickly and to achieve short delivery times.

High Quality

ISO9001, ISO13485 and IATF16949 certified production lines are indicators of the high quality standard of our products and ensure your safety and satisfaction.

All products come from a largely automated process with automatic soldering and crimping and 100 percent electrical testing. Our distribution and logistics processes are certified according to ISO9001 and audited according to VDA.

All products come from a largely automated process with automatic soldering and crimping and 100 percent electrical testing. Our distribution and logistics processes are certified according to ISO9001 and audited according to VDA.

Tests

You require specific tests, such as bending cycles, lengths or test reports? If so, ElectronAix is the perfect partner for you. We will coordinate all details with you individually.

"In cooperation with you, we develop the best solution for your application, entirely according to your needs. Our strength are series from 100 or 1000 pieces and customer-specific jacket cables from 1000 m or 3000 m. You receive a drawing for approval and samples for approval; after approval, the material and production site remain unchanged. The series products are always produced 100% as sampled: always from the same production, always with the same material."

Your personal contact for cable assemblies PVC + PUR

Mr. Kai Fröhlich

+49-241-18906-91

+49-241-18906-91

kai.froehlich@electronaix.com

kai.froehlich@electronaix.com

.png) Contact form

Contact form

Mr. Kai Fröhlich

kai.froehlich@electronaix.com

kai.froehlich@electronaix.com